|

|

|

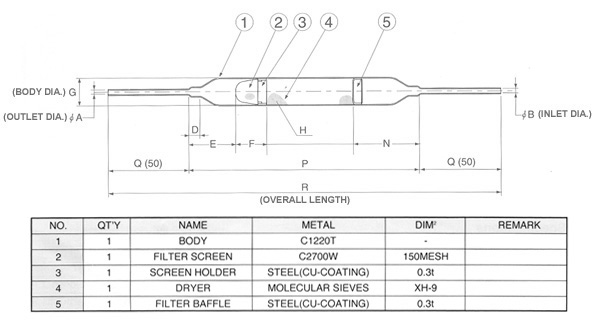

| - Nara's liquid line and suction line filter-driers

are often referred to as System Protectors because they remove harmful

elements from the circulating refrigerant before serious damage results.

Keeping the system clean and free of foreign contaminants that can

restrict the operation of valves, block capillary tubes or damage

compressors is the best way to assure trouble-free operation. These

contaminants can be solids, such as metal filings, flux, dust and

dirt. Other equally menacing contaminants are solubles, such as acid,

water, resins and wax. The bead style filter-drier uses a less complicated

manufacturing process, so there is less change of error. The active

drying material is in the form of beads or pellets. No bonding material

is used to hold the beads together, but rather compacting is normally

performed through some type of mechanical pressure. On the upstream

side of the compacted beads is a filter network which cushions flow

and traps the solid contaminants. Nara filter-driers protect the refrigerant

system from liquid and solid contaminants. |

|

- Filtration first for more effective use

of surface area of desiccant.

- Soluble contaminant capacities for water, acid. Cushioned flow for

non-turbulent performance.

- Process controlled fiberglass filter network for premium filtering.

- Corrosion resistant epoxy power paint finish.

- Rugged steel shells for shock resistance. Low pressure drop-full

flow fitting.

- Furnished with seals to prevent moisture penetration.

- Maximum design pressure is 500psiG.

- Compatible with CFC, HCFC and HFC refrigerants.

- May be mounted in any position easily. |

|

|

|

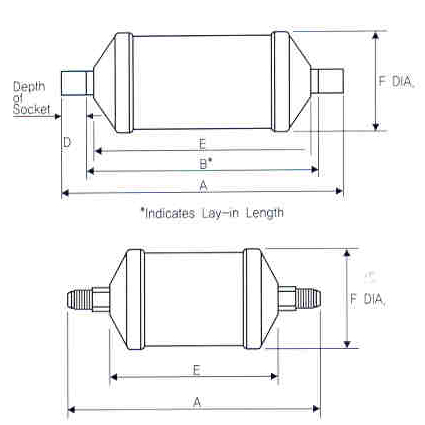

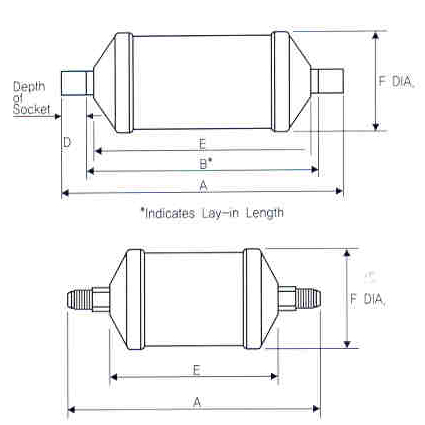

MODEL NO. |

CONNECTION |

DIMENSION (mm) |

|

A |

B |

D |

E |

F |

| NFD-032 |

1/4"

SAE |

4-3/8 |

|

|

2-9/16 |

1-5/8 |

| NFD-032S |

1/4"

ODF |

3-7/8 |

3-1/8 |

3/8 |

| NFD-052 |

1/4"

SAE |

4-13/16 |

|

|

3 |

5-5/8 |

| NFD-052S |

1/4"

ODF |

4-7/16 |

3-11/16 |

3/8 |

| NFD-053 |

3/8"

SAE |

5-1/8 |

|

|

| NFD-053S |

3/8"

ODF |

4-1/2 |

3-5/8 |

4/9 |

| NFD-082 |

1/4"

SAE |

5-5/8 |

|

|

3-13/16 |

2-5/8 |

| NFD-082S |

1/4"

ODF |

5-1/4 |

4-1/2 |

3/8 |

| NFD-083 |

3/8"

SAE |

5-15/16 |

|

|

| NFD-083S |

3/8"

ODF |

5-5/16 |

4-7/16 |

4/9 |

| NFD-084 |

1/2"

SAE |

6-3/16 |

|

|

| NFD-084S |

1/2"

ODF |

5-3/8 |

4-3/8 |

4-3/8 |

| NFD-163 |

3/8"

SAE |

6-7/8 |

|

|

4-3/4 |

2-5/8 |

| NFD-163S |

3/8"

ODF |

6-1/4 |

5-7/6 |

4/9 |

| NFD-164 |

1/2"

SAE |

7-1/16 |

|

|

| NFD-164S |

1/2"

ODF |

6-5/16 |

5-5/16 |

1/2 |

| NFD-165 |

5/8"

SAE |

7-1/2 |

|

|

| NFD-165S |

5/8"

ODF |

6-9/16 |

5-5/16 |

5/8 |

| NFD-304 |

1/2"

SAE |

9-7/8 |

|

|

7-1/2 |

3-1/16 |

| NFD-304S |

1/2"

ODF |

9-1/8 |

8-1/8 |

1/2 |

| NFD-305 |

5/8"

SAE |

10-5/16 |

|

|

| NFD-305S |

5/8"

ODF |

9-5/16 |

8-1/6 |

5/8 |

| NFD-306S |

3/4"

ODF |

9-11/16 |

8-7/16 |

5/8 |

| NFD-307S |

7/8"

ODF |

9-7/8 |

8-3/8 |

3/4" |

| NFD-309S |

1-1/8"

ODF |

10-1/4 |

8-7/16 |

1 |

| NFD-414 |

1/2"

SAE |

10 |

|

|

7-5/8 |

3-11/16 |

| NFD-415S |

5/8"

ODF |

9-7/16 |

8-3/16 |

5/8 |

| NFD-417S |

7/8"

ODF |

10 |

8-1/2 |

3/4 |

| NFD-419S |

1-1/8"

ODF |

10-5/16 |

8-1/2 |

3/4 |

| NFD-757S |

7/8"

ODF |

15-7/16 |

13-15/16 |

3/4 |

13-1/16 |

| NFD-759S |

1-1/8"

ODF |

15-3/4 |

13-7/8 |

15/16" |

|

|

|

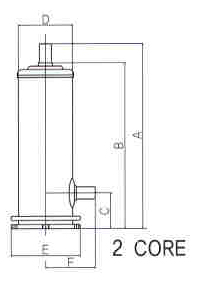

Shell |

No. of Cores |

Connections |

Dimensions(inch) |

|

Inlet |

Outlet |

A |

B |

C |

D |

E |

F |

| NFDS-485 |

1 |

5/8 |

5/8 |

246 |

206 |

76 |

114 |

146 |

105 |

| NFDS-487 |

7/8 |

7/8 |

| NFDS-489 |

1 1/8 |

1 1/8 |

| NFDS-4811 |

1 3/8 |

1 3/8 |

| NFDS-4813 |

1 5/8 |

1 5/8 |

| NFDS-4817 |

2 1/8 |

2 1/8 |

| NFDS-967 |

2 |

7/8 |

7/8 |

390 |

350 |

| NFDS-969 |

1 1/8 |

1 1/8 |

| NFDS-9611 |

1 3/8 |

1 3/8 |

| NFDS-9613 |

1 5/8 |

1 5/8 |

| NFDS-9617 |

2 1/8 |

2 1/8 |

|

| ¢Á Drier For Units Up Copper Drier

|

|